R&M Sheetmetal Nowra Metal Roofing

Aluminium Fabrication in the Shoalhaven

- Custom Fabrication Experts

- Trusted Metal Roofing Supplier

- 75+ Years’ Combined Experience

Request a Call Back

Contact Us

Thank you for contacting R&M Sheetmetal Nowra Metal Roofing.

We will be in touch soon.

Oops, there was an error sending your message.

Please try again later.

Lightweight, Reliable Aluminium

Aluminium is widely chosen for its strength-to-weight ratio and excellent corrosion resistance, making it ideal for both structural and architectural applications. While it can be fabricated with or without heat, certain processes may increase brittleness if not handled correctly. That’s why professional guidance during the design stage is essential to ensure durability, performance, and cost efficiency.

We provide specialised aluminium fabrication, welding, and supply services onsite, delivering high-quality workmanship tailored to your project requirements, including:

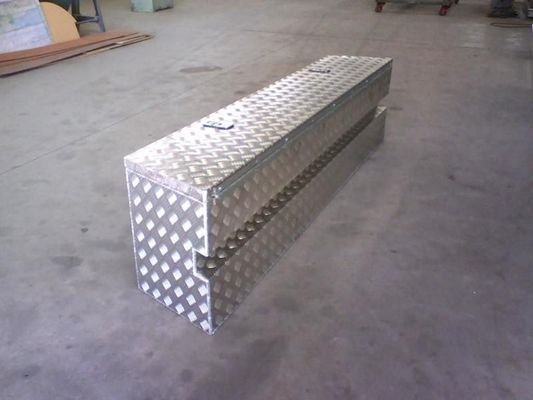

- Custom made tool boxes and repairs

- Aluminium fabrication, welding & cutting

- Trailer repairs

- Safety trays

Locations We Service

Frequently Asked Questions

What is aluminium fabrication used for?

Aluminium fabrication is used across a wide range of industries including construction, transport, manufacturing, architecture, and marine applications. Its strength, corrosion resistance, and lightweight nature make it ideal for products like window frames, structural components, outdoor furniture, signage, cladding panels, enclosures, and toolboxes.

Aluminium is also popular for custom projects that require a specific shape or profile, as it can be easily cut, bent, and welded to meet precise specifications. Its modern appearance and durability make it suitable for both functional and decorative applications in residential, commercial, and industrial settings.

Is aluminium easy to weld and shape?

Aluminium is generally considered easy to work with due to its malleability, but it requires specific welding techniques and experience to ensure clean, durable results. Unlike steel, aluminium has a lower melting point and higher thermal conductivity, which means it can distort or weaken if not handled correctly.

TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding are commonly used for aluminium, depending on the thickness and application. Because the material can become brittle under certain conditions, it's important to use the right temperature, filler rods, and post-weld treatments. With proper equipment and expertise, aluminium can be shaped and welded into complex forms with a clean finish.

What are the advantages of using aluminium in fabrication?

Aluminium offers a number of benefits that make it a preferred material in fabrication. It is significantly lighter than steel, which reduces overall weight in structural applications and transportation. It also naturally resists corrosion without the need for additional coatings, making it suitable for outdoor and coastal environments.

Aluminium is recyclable, non-toxic, and has a modern aesthetic that works well in architectural designs. Its flexibility allows it to be extruded or formed into a wide variety of shapes, and it can be machined with high precision. These qualities make aluminium ideal for both functional builds and high-end finishes.