R&M Sheetmetal Nowra Metal Roofing

Sheet Metal Fabrication in the Shoalhaven

- Custom Fabrication Experts

- Trusted Metal Roofing Supplier

- 75+ Years’ Combined Experience

Request a Call Back

Contact Us

Thank you for contacting R&M Sheetmetal Nowra Metal Roofing.

We will be in touch soon.

Oops, there was an error sending your message.

Please try again later.

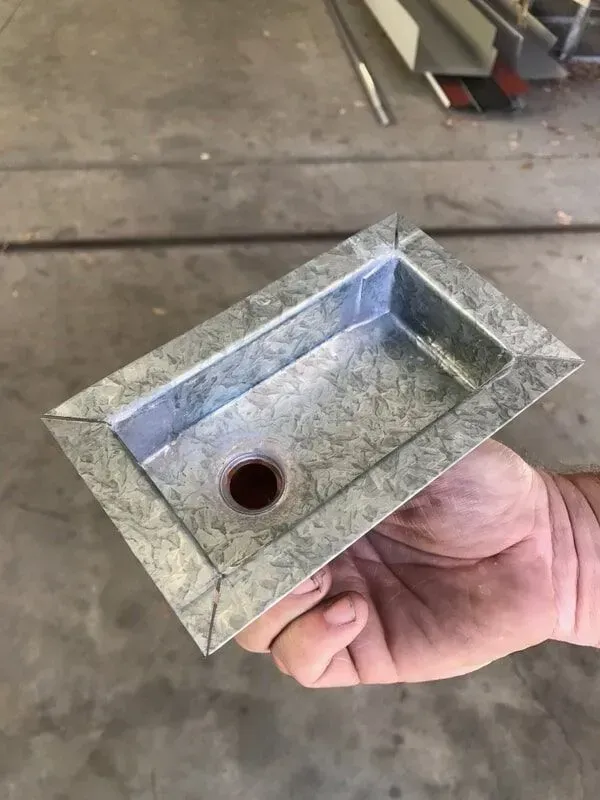

Custom, Professional Metalwork

At R&M Sheetmetal, we provide sheet metal fabrication services for customers across the Shoalhaven region. Our workshop is equipped with CNC Press Brake, 6m and 3m folders and 2.5m guillotines, allowing us to work with .55 to 3mm gauge thickness and produce components to a 0.5mm tolerance.

We manufacture custom metal products to suit the requirements of industry, commercial trades, homeowners and DIY users. Our team also offers MIG, TIG and aluminium welding to support a wide range of projects.

All fabrication is completed using high-quality materials to ensure strength and reliability in any application. For sheet metal fabrication in Shoalhaven, call us on (02) 4421 0054.

Efficient Airflow & Ducting Systems

At R&M Sheetmetal, we manufacture air-conditioning ducting for both commercial and domestic applications across Nowra and the Shoalhaven region. We work extensively with local refrigeration and air supply trades to provide them with their specialised needs.

Using CNC machinery, we create ducting that fits perfectly and operates the way it should. We will manage fabrication closely to ensure quality control and faster turnaround. Need help with airflow and ventilation? Give us a call on (02) 4421 0054 and we’ll sort it out with an air control solution that fits.

Locations We Service

Frequently Asked Questions

What is sheet metal fabrication and how does it work?

Sheet metal fabrication is the process of transforming flat sheets of metal—such as steel, aluminium, or stainless steel—into finished products or components using various techniques. These techniques include cutting, bending, folding, punching, welding, and assembling.

The process often begins with computer-aided design (CAD) to create precise plans, which are then executed using machinery like CNC (Computer Numerical Control) cutters, press brakes, and guillotines.

Sheet metal fabrication is widely used across industries including construction, automotive, HVAC, and manufacturing. It allows for high precision, fast turnaround, and customisation based on specific dimensions or project requirements.

What materials are commonly used in sheet metal fabrication?

The most common materials used in sheet metal fabrication are mild steel, stainless steel, aluminium, brass, and copper. Each material offers unique benefits depending on the application. For example, aluminium is lightweight and corrosion-resistant, making it ideal for marine or coastal projects. Stainless steel is strong and resistant to staining, commonly used in kitchens and medical environments.

Mild steel is highly formable and cost-effective, often used for structural applications. The choice of material depends on factors like strength requirements, environmental exposure, aesthetic preferences, and budget.

What is CNC sheet metal fabrication?

CNC sheet metal fabrication refers to the use of computer-controlled machinery to carry out fabrication processes with extreme precision and consistency. CNC stands for “Computer Numerical Control,” and it’s used in equipment like press brakes, routers, and cutting machines. These systems follow programmed instructions to cut, bend, and shape metal to exact specifications—often down to a tolerance of less than 1mm.

CNC fabrication reduces human error, increases efficiency, and is particularly useful for repetitive, high-volume, or highly detailed work. It's a popular choice in industries that require accuracy and speed, such as aerospace, construction, and electronics.