R&M Sheetmetal Nowra Metal Roofing

Stainless Steel Fabrication and Products in the Shoalhaven

- Custom Fabrication Experts

- Trusted Metal Roofing Supplier

- 75+ Years’ Combined Experience

Request a Call Back

Contact Us

Thank you for contacting R&M Sheetmetal Nowra Metal Roofing.

We will be in touch soon.

Oops, there was an error sending your message.

Please try again later.

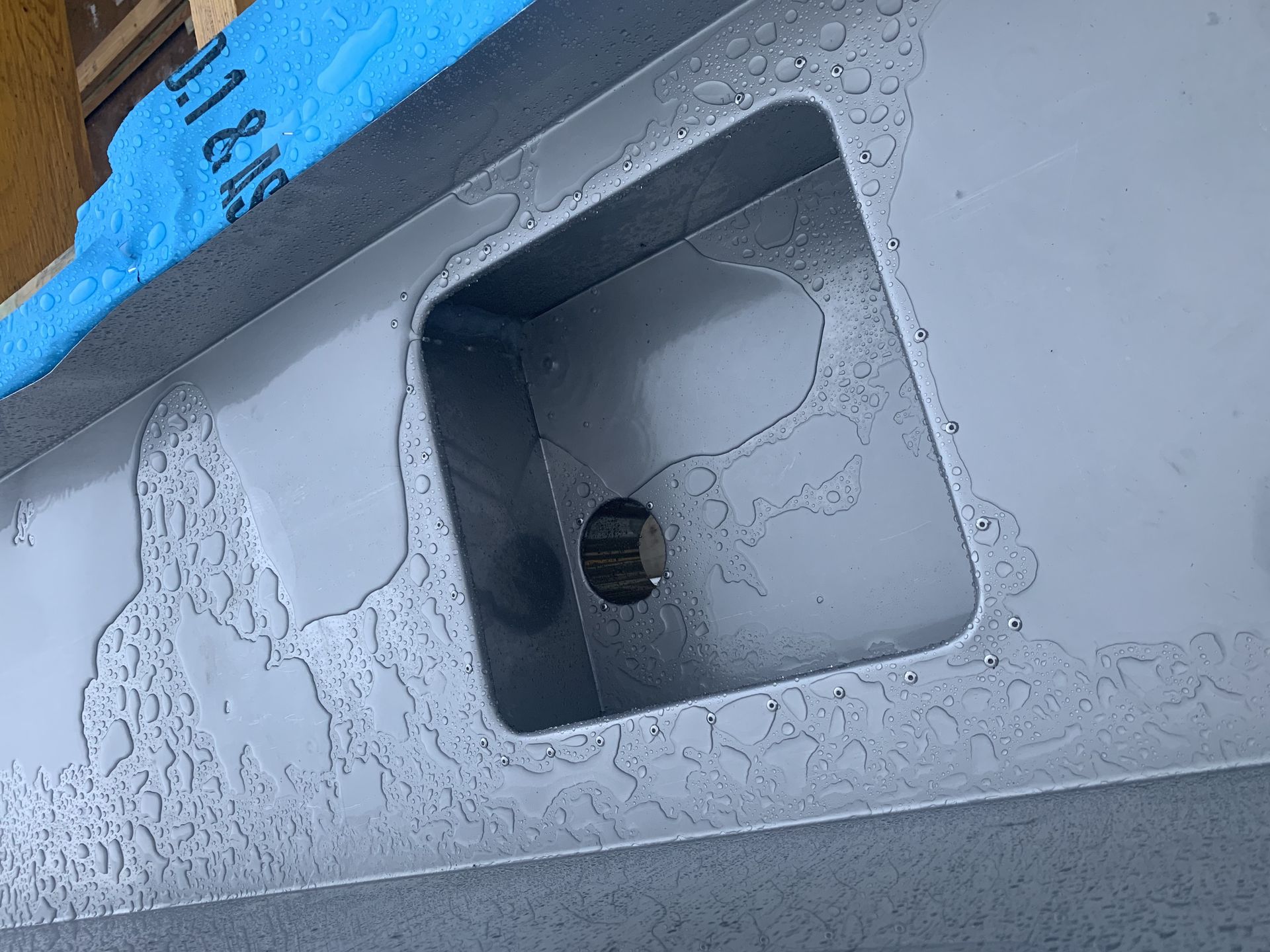

High-performance Stainless Steel Builds

If you are looking to create a custom stainless steel kitchen for a commercial or domestic property, R&M Sheetmetal is the fabrication business in Nowra to call.

Stainless steel bench tops, splashbacks and sink stations are proven to be highly hygienic and can add value to your home through stylish sophistication.

We offer a highly specialised fabrication of stainless steel kitchen and laundry benches, shelving and hoods to suit your specific requirements, décor and budget.

Commercially, we manufacture high-grade specialised stainless steel products for any area deemed necessary for your restaurant, café or kitchen and also for hospital, operating theatres and clinical applications.

Locations We Service

Frequently Asked Questions

What is stainless steel fabrication used for?

Stainless steel fabrication is used to create a wide range of products and components for residential, commercial, industrial, and architectural applications. Because of its durability, corrosion resistance, and clean finish, stainless steel is commonly used in kitchens (benches, splashbacks, sinks), handrails, balustrades, medical equipment, food processing machinery, commercial fit-outs, and custom-made brackets or frames.

In construction and engineering, it’s also valued for its structural integrity and ability to withstand harsh environments. The fabrication process may include cutting, bending, welding, and polishing to achieve a final product that meets exact design and performance requirements.

What are the benefits of using stainless steel for fabrication projects?

Stainless steel offers a number of advantages that make it ideal for fabrication projects. It’s highly resistant to corrosion and staining, which means it performs well in humid, wet, or chemically exposed environments—like kitchens, coastal buildings, or industrial facilities.

It’s also strong yet lightweight, easy to clean, and long-lasting, reducing the need for frequent repairs or replacements. Stainless steel has a modern appearance, making it popular for visible applications like signage, benches, and decorative finishes. Additionally, it’s recyclable and environmentally friendly, making it a sustainable choice for both small-scale and large-scale projects.

Can stainless steel be welded or customised easily?

Yes, stainless steel can be welded and customised with a variety of fabrication techniques. Modern fabrication workshops use tools like CNC machines, press brakes, and TIG or MIG welders to shape and assemble stainless steel components accurately.

However, stainless steel does require specific welding practices to prevent warping, maintain corrosion resistance, and achieve a clean, strong finish. For example, using the right filler materials and post-weld treatments like passivation can ensure a professional result.

With the right expertise and equipment, stainless steel can be fabricated into complex, custom shapes for a wide range of practical and aesthetic purposes.